Business owners can turn to us when they need reliable commercial roofing services.

When you own or manage a business, taking care of building maintenance tasks can often fall by the wayside. Instead of vacuuming the floors, for instance, you may choose to work on essential tasks that will keep your business on track. Although this practice is typically harmless, there is one vital component of your building that you should never ignore: your commercial roofing.

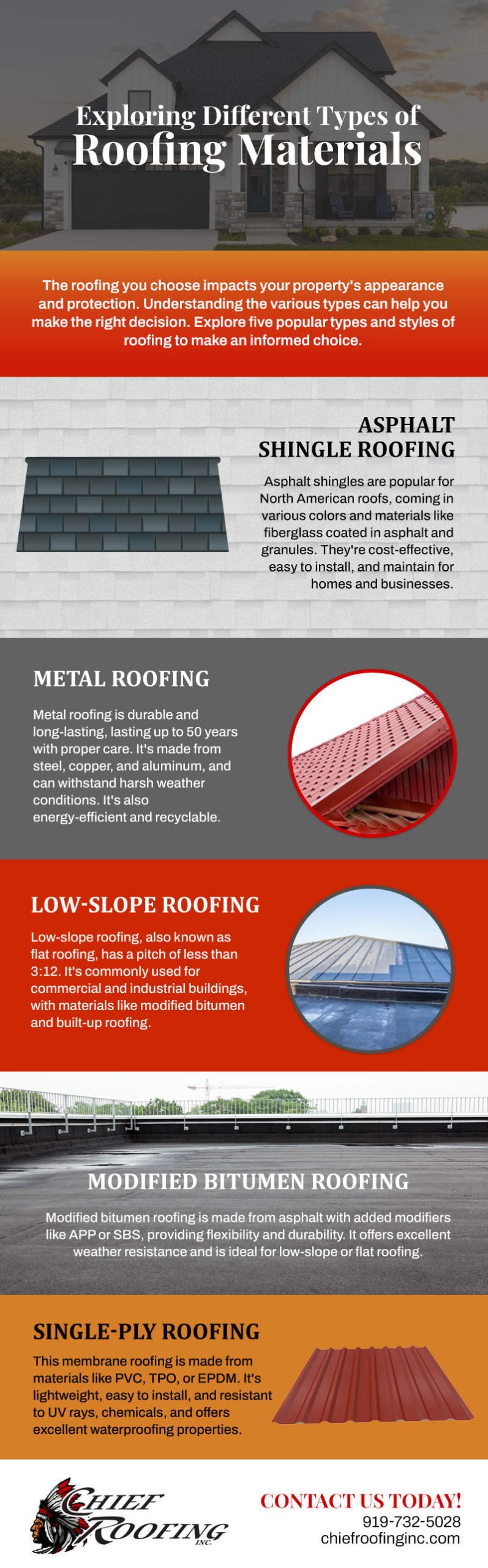

You rely on your building’s roof to keep your office safe and secure, but in order to do this for years on end, your roof needs some regular professional attention. This is where our team can help. Here at Chief Roofing, we’re dedicated to providing exceptional commercial roofing services for properties throughout the Hillsborough, North Carolina area.

If you’re not sure who to trust for your commercial roofing needs, we encourage you to reach out to our team. We’re the most experienced roofing company in the area, and as a locally owned and operated business, we would be honored to help other business owners maintain their roofs. If you have any questions or would like to schedule a commercial roofing service, please contact us today.

At Chief Roofing, we provide commercial roofing services in Hillsborough, Chapel Hill, Durham, Pittsboro, Holly Springs, Apex, Morrisville, Raleigh, Cary, Mebane, Wake Forest, Knightdale, and Efland, North Carolina.